Innovation

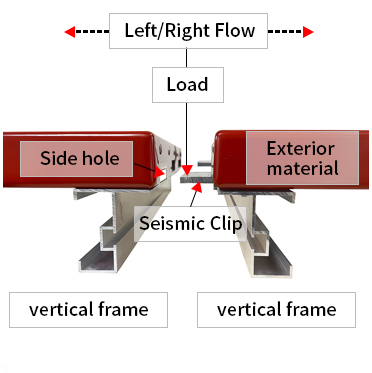

Ensuring arthquake resistance

Prevent frame deformation, detachment, and breakage,

Preventing secondary damage from earthquakes

PRODUCT

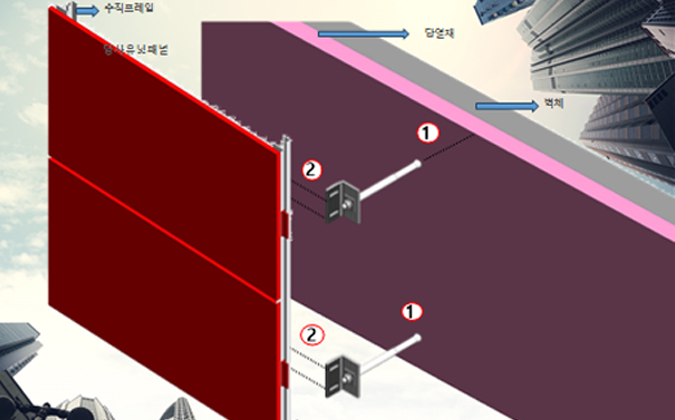

Earthquake-resistant unit system panel

40% reduction

Cost savings of 15.7%

Preventing secondary damage from earthquakes

Fire prevention through non-welding methods

Improved uniform manufacturing,

construction quality and productivity

Improved heat transfer through

robust joint connections

Construction is possible regardless of whether

a ladder is installed or not.

The application of integrated panel system technology has shortened the construction process and period.

It is an innovative, economical, and convenient earthquake-resistant panel.

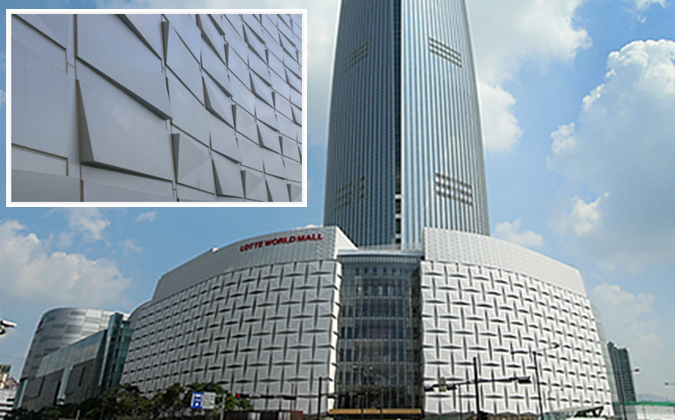

| Construction site | Construction method and examples |

|---|---|

| Entire exterior wall of Lotte Super Tower Avenue L Building, Jamsil | Exterior panel grid maximizing 3D effect, wave pattern maximizing high-quality image |

| Jangheung Sports Education Center, Korea Sports Council | Earthquake-resistant unit system panel |

| Sejong City Government-funded research institute | Alum. Panel Cladding Wall |

| Anyang Pyeongchon Hillstate | |

| Jeju Provincial Police Agency | |

| Ulsan Safety Experience Center | Korea Electric Power Corporation building |

| National Pension Service Building 2 | Gangwon-do Agricultural Technology Institute |

| Chungbuk National University Hospital | 2nd Air Traffic Center |

| Gunpo Songjeong Complex Sports Center | Korea Electric Safety Corporation building |

Ensuring arthquake resistance

Prevent frame deformation, detachment, and breakage,

Preventing secondary damage from earthquakes

| division | Step 1 | Step 2 | Step 3 | Step 4 | Step 5 | Construction period |

|---|---|---|---|---|---|---|

| Existing products |

Anchor, bracket installation

It takes 10 days

|

Subframe welding fabrication

It takes 10 days

|

Subframe Welding Installation

It takes 15 days

|

Panel Installation

It takes 12 days

|

Silicone

It takes 11 days

|

It takes a total of 58 days |

| Our excellent products |

Anchor installation

It takes 10 days

|

Shortened processing time (total 25 days)

|

Unit panel installation

It takes 10 days

|

Silicone

It takes 10 days

|

It takes a total of 30 days | |

※ It has a 40% air shortening effect compared to existing products. (Cost savings)

| Division | Truss | Construction worker skill level | To weld or not to weld | Materials |

|---|---|---|---|---|

| Existing products | On-site assembly and construction | Quality stability is fluid | On-site welding | Risk of corrosion of steel frames, brackets, anchors, etc. |

| Our excellent products | Factory manufactured and installed on site |

Applying a modular system. Ensuring quality stability with simple assembly |

Weldless (assembled) |

No need to worry about corrosion with aluminum bracket |

※ Fire prevention effect due to absence of on-site welding .